We've had the pleasure of working with our manufacturing facility in York for a long time and have seen the development of many of the long-standing equipment, we love today.

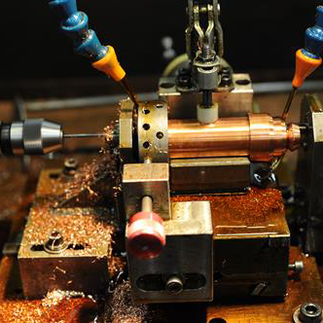

This manufacturing facility operates with state-of-the-art CNC machines that are capable of producing high-quality cutting nozzles and brass fittings. For a wide range of applications, from the fabrication shop to heavy steel mill equipment.

With advanced technology and ultra-modern manufacturing techniques, we can offer the most reliable, heavy-duty, and hard-wearing products. That has been manufactured just up the M1.

The only UK manufacturer of cutting nozzles and torches based in York that is completely dedicated to providing quality British manufactured products. Who can manufacture bespoke items for a wide range of customers covering many fields including gas cutting and welding, the steel industry and railways.

The ANM and PNM range of cutting nozzles will cut safer and more efficiently with a suction feature and have been manufactured to give an efficient performance before leaving the factory each one is individually tested.

See below some cutting nozzle tested

Not only are they able to manufacture standard equipment such as many different types of hose and regulator fittings for the global markets but are also the go-to when creating bespoke one-off valve assemblies and connection blocks to more specialised heating torches and water-cooled cutting equipment.

Our relationship has been embedded in Truflame's history. In the very beginning, Truflame started out by repairing cutting torches. As well as our name "Truflame," is derived from the precision required in setting up the flame of a cutting nozzle. It encapsulates the company's dedication to excellence. The design of the logo was created in the image of a Headnut of a cutting torch that retains the nozzle, which reflects the origin of the name created by Stephen Gavins. (Learn more about our beginnings.)

Invest in British Manufacturing!

A cutter that lasts a lifetime - Why would you choose anything else, when you can get your hands on a cutting torch that is fully repairable with a lifetime warranty? Our skilled and trained team repairs and services these cutting torches. During this process, our team carries out a visual inspection to check for damages and possible repairs. Our flat-handle cutter is built to withstand our industry and keep your torch working at its best. There are two basic forms of hand cutting, the NM (Nozzle Mix) in which the fuel gas and oxygen are mixed in the nozzle. The Universal (MS) where the gases are mixed in the cutting torch head. These torches are British-made, Fully Repairable, can be used with Acetylene or Propane nozzles and are available in a range of lengths.

Cut safer with our cutting nozzles - Hi-Lo ANM / PNM nozzles are precision manufactured to give an efficient performance and before leaving the factory, each one is individually tested to ensure suction to the acetylene line, quality of the pre-heat flame and accuracy of the oxygen cutting stream. Hi-Lo nozzle design illustrated (acetylene version) limits the amount of explosive oxy/fuel gas mixture to the low volume of the drilled and swaged pre-heat passages in the solid copper from which the nozzle is made.

After something a little special? - Working alongside Hi-Lo allows us to manufacture bespoke items for your needs. With the knowledge and expertise to cover many industries, from gas cutting and welding to steel industry and rail. Due to our partnership and closely working with the factory up the road, we can help you with your bespoke needs and can offer various brassware including screwed coupler and nut & tail. Get in touch with our team!

With this facility, we can provide the very best British-manufactured gas cutting and welding equipment for your needs. Whether you need standard gas equipment or something more bespoke we can help you get the right premium equipment.

Comments